Small Seawater Desalination System – Marine Models Supplied by Anyikang

Seawater, due to its high salt content, cannot be used directly. There are two main methods for desalination: distillation and reverse osmosis.

Distillation is primarily used in large-scale seawater treatment facilities and areas with abundant thermal energy.

Reverse osmosis (RO) membrane technology, on the other hand, offers high desalination efficiency and wide applicability.

As a result, RO-based seawater desalination systems are now widely adopted, especially for small and medium-sized marine applications.

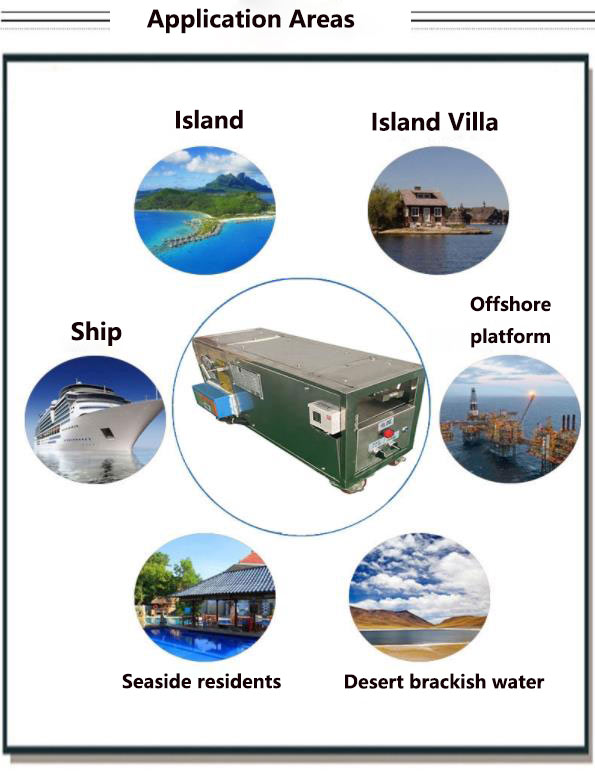

Anyikang provides compact, marine-grade desalination systems designed for boats, ships, and offshore use.

Small Seawater Desalination Systems – Marine Models Supplied by Dongguan Anyikang Technology Co., Ltd.

Seawater, due to its high salinity, cannot be used directly. There are two primary methods for desalination: distillation and reverse osmosis (RO).

Distillation is mainly applied in large-scale desalination projects or areas with abundant thermal energy.

Reverse osmosis, on the other hand, is widely used due to its high desalination rate and broad applicability.

In an RO desalination system, seawater is first extracted and pretreated to reduce turbidity and prevent the growth of bacteria, algae, and other microorganisms.

Next, a specialized high-pressure pump increases the pressure, allowing the seawater to pass through reverse osmosis membranes.

Given the high salinity of seawater, RO membranes must offer high salt rejection, corrosion resistance, high-pressure tolerance, and anti-fouling performance.

After treatment, the total dissolved solids (TDS) of seawater are reduced from around 36,000 mg/L to approximately 200 mg/L.

The resulting freshwater often exceeds the quality of municipal tap water and can be used for industrial, commercial, residential, and marine applications, including ships and naval vessels.

1. Seawater Sterilization and Algae Removal

Seawater contains a large number of microorganisms, bacteria, and algae. Their growth and reproduction can damage water intake facilities and severely impact the operation of seawater desalination equipment and process pipelines. Therefore, seawater desalination projects typically use chemical agents such as liquid chlorine, sodium hypochlorite, and copper sulfate to sterilize and control algae growth.

2. Coagulation and Filtration

Due to tidal changes, seawater often carries large amounts of sediment, resulting in high and fluctuating turbidity. This can cause instability in the pretreatment system. Coagulation and filtration are added to remove colloids and suspended solids in seawater and reduce turbidity.

In reverse osmosis systems, the Silt Density Index (SDI) is commonly used to evaluate water quality. The feed water entering the RO membranes should have an SDI of less than 4.

Because seawater has high specific gravity, pH, and seasonal temperature variations, ferric chloride is often used as a coagulant for its excellent performance in various temperatures, strong floc formation, and fast sedimentation.

3. Mechanical Filtration

To further reduce turbidity and improve the feed water quality for reverse osmosis, a sand filter is typically installed after coagulation and filtration. It helps remove fine suspended solids and particulate matter, ensuring more stable and reliable water for downstream processes.

4. Antiscalants and Reducing Agents

Seawater has a complex composition with high hardness and alkalinity. To ensure the RO system operates without scaling, appropriate antiscalants must be added based on specific water quality.

In addition, oxidants added during pretreatment (for sterilization) must be neutralized before entering the RO system. Reducing agents are used to lower residual chlorine to below 0.1 ppm (or ORP < 200 mV), meeting the safety requirements for reverse osmosis membranes.

5. Security (Fine) Filter

Due to the high salinity of seawater, 316L stainless steel is used for security filter housings. Filter cartridges typically have a pore size of 5 microns. These filters are placed before the high-pressure pump to block particles larger than 5μm, thereby protecting the high-pressure pump, energy recovery device, and RO membranes for long-term, stable operation.

✅ Low Energy, Long Service Life

Equipped with advanced RO membrane technology and carefully selected components, ensuring low energy consumption, long-lasting performance, and minimal maintenance costs.

✅ Safe & Stable Drinking Water Quality

Real-time monitoring and a reliable maintenance system guarantee consistently stable water quality that meets national drinking water standards and certifications.

✅ Intelligent Protection System

Smart control with high/low-pressure protection switches automatically adjusts operations, triggers alarms, and shuts down when necessary—protecting the high-pressure pumps and RO membranes.

✅ Modular Design for Easy Installation

A modular layout optimizes space utilization and makes installation faster and easier, while offering flexibility to meet different project needs.